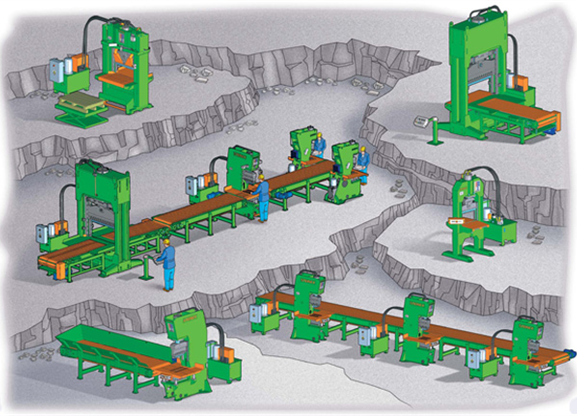

Building Stone Processing Facilities

At Apex Equipment International, Inc., we know your stone processing center is the backbone of your business, which is why we offer innovative, mission-critical solutions that offer you better availability, improve efficiency, longevity and offer flexible, scalable systems that meet the specific needs of your business.

At Apex Equipment International, Inc., we know your stone processing center is the backbone of your business, which is why we offer innovative, mission-critical solutions that offer you better availability, improve efficiency, longevity and offer flexible, scalable systems that meet the specific needs of your business.

Because of the pivotal role we play in your business, Apex Equipment International is committed to creating and maintaining strong relationships with our customers, built on a foundation of excellence and trust. From the equipment we import from Italy to our dedicated customer service and support, we know what’s important to you. Andre Hagadorn, through his many years as an owner/operator, of his Upstate New York Granite Processing facility, has experienced the benefits of Steinex Splitting equipment. As a Quarrier of multiple surface mines, he has seen what granite can do to splitting equipment, and through his research and hands on knowledge of this type of equipment and stone, he has found a line of guillotines that stand the test of time.

About Steinex, Srl.

About Steinex, Srl.

For more than 35 years, Steinex has been designing, manufacturing and distributing personalized production lines for all types of natural stone and concrete products. This extensive experience has made us known to all key players in the industry and recognized as an international leader

Our mission is to listen to our client's specific needs and deliver high performance products through continuous product innovation and operational excellence. We carry complete product lines from the "C" Frame Igloo, to the "H" frame Broadway, Windstar and Menhir. We also carry motorized, pivoting and non pivoting conveyors as well as custom automated production lines.

|

|

IGLOOCobbles, pavers and wall stones Igloo stone splitting machines are strong, versatile and above all fast. They are outstanding for the speed with which they can produce large quantities of split stone. |

|

BROADWAYTiles and flat finished |

|

WIND STARMachines for automatic CNC systems Wind Star is the CNC splitting machinery widely used in automatic splitting lines for both concrete and natural stone. The Wind Star can work material of any type or dimension. For sawn or manufactured blocks the machine is equipped with four blades to ensure a perfect split each time on all fours sides of the block. Wind Star technology is cutting edge on high production automatic lines and can be incorporated into lines with robotic feeding and palletizing of finished products. |

|

MENHIRCurbstones and semi-finished products |

|

SHERPAConveyor systems Sherpa conveyors are the ideal solution for the loading and unloading of material for splitting machines, a solution essential for maintaining a continuous and efficient production cycle. |